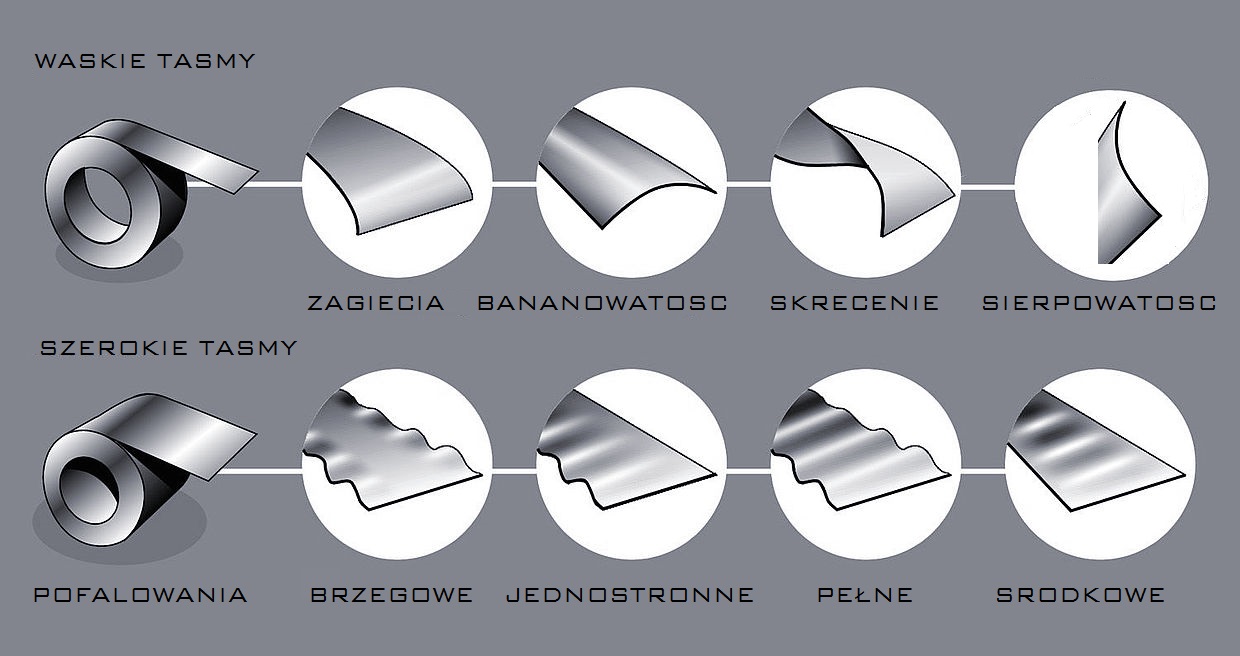

Steel defects

Steel defects

- Tape fold:

Crease is one of the most common defects. The defect is caused by plastic deformation during the winding process. The bend in the coil can be sufficiently straightened with 7 to 13 straightening rollers. Roller straighteners with basic adjustment, i.e. with the lower and upper leveling rollers positioned parallel to each other, are well suited for this purpose.

- Transverse curvature:

Aligning the transverse arch is more difficult. The reason for this inequality is uneven cooling of the material over the entire width of the coil (residual stresses). Straighteners with parallel arrangement of straightening rollers reduce the transverse curvature as the number of straightening rollers increases. The best results are obtained with 17 or more narrow straightening rollers.

- Twist:

This defect occurs when there are strong changes in belt tension or too little tension during the winding process. As in the case of compensation of transverse curvature, here too the best results are achieved with 17 or more straightening rollers with a narrow pitch.

- Sickle cell disease (saber):

Severe sickling usually only appears in narrow ribbons created by cutting. There are two ways to fix the error.

So-called vertical straightening devices are used. In cooperation with the straightener, they create the necessary bend of the material over the high edge. However, the application of this principle is severely limited by the high edge pressures required with the risk of edge deformation. It is performed by transversely tilting the upper rolling roll. The adjustment is made so that the short side of the belt is tight.

- Material breakage:

This flatness error usually occurs when strips of hot rolled sheet metal are unwound. Serious fractures can be significantly reduced with the use of high-performance extensors, but cannot necessarily be completely eliminated.

- Edge and central corrugation:

These defects usually occur with wide and thin sheets. They are caused by internal stresses that occur during the rolling process. Such defects cannot be straightened using parallel straightening rollers.

For edge waves, the center of the sheet should be extended to the same length as the edges of the sheet.

For center folds, the edges of the sheet should be extended to the same length as the center of the sheet.